So why are we here, and how are we not crazy?

It's quite simple, really. The Space Industry has been stagnating since the '70's. Almost all work is cost-plus, where you are punished with lower revenue if you are more efficient. Public perception takes priority over project success, resulting in enormous cost just to cover one's rear-end. And finally, the behemoths that have monopolized the space industry have no incentive to ever change.

In other words, what we have here is a multi-billion dollar opportunity.

SpaceX has introduced the world's first all-new orbital rocket design in over 10 years. The reason is that the existing designs, based on technology from the '70's, were high cost and low reliability. Not a great combination as it turns out. SpaceX looked at what was out there and decided to try a different approach: low cost and high reliability. It's a simple rocket, and that's the point.

It's also the only semi-reusable rocket apart from the Space Shuttle. All other rockets are single-use only.

The SpaceX launch team in Kwaj is less than 30 people. When another rocket company launches in Kwaj, they bring 300 people. What they do here is beyond us.

The entire SpaceX team on Kwaj.

When other rocket companies need something done, they requisition the right forms, talk to the right people, go back to the right forms, try again with another set of right people, go back to the forms (also known as the TPS reports), and eventually go a little more postal each day.

When SpaceX needs something done, they do it, and they do it fast.

Case in point:

On Saturday night it was discovered that the power distribution boards were not operating properly and that the capacitors needed to be upgraded. This is very difficult to fix on a remote tropical island 5,000 miles away from America.

On Sunday, they lowered the rocket, separated the two stages and removed the boards - just in time for one of the SpaceX engineers to hop on a plane back to California. The team then found a supplier for the capacitors that was open on Sunday. They were in Minnesota. Immediately an intern was put on a plane to fly up and get the capacitors.

The engineer and the intern got back to the SpaceX offices at about the same time. 2:45pm Monday. Over the next 8 hours, they replaced the capacitors on the boards, tested them for their ability to withstand heat, cold and vibrations, and packaged them for the trip back. They got on a plane at 10:30pm and arrived in Kwaj this morning at 6am.

They then spent the day replacing the boards and re-attaching the stages. As of 5pm Kwaj time, the rocket is attached and they are about to re-erect it. Total turn-around time: 80 hours.

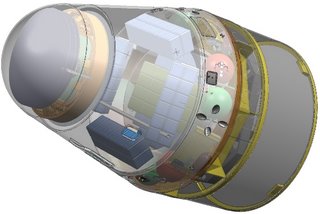

Falcon 1 with stages separated as they install the boards.

Bulent Altan - the Engineer who flew back to CA, now in the 50th hour of his day

So yes, pretty crazy. But in a good way. ;)

By the way, did I say I flew in a Huey today?

K

****Note: this blog is for entertainment purposes only and intended only for viewing by my friends. This is not endorsed by SpaceX, or part of SpaceX's official communications. Please don't trust a word I say. Really. For all you know, I'm making it all up and I'm actually sitting in my basement somewhere in Boulder.

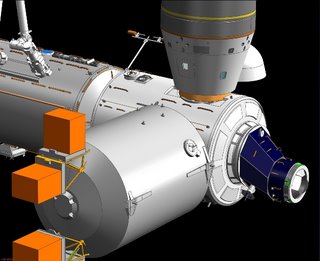

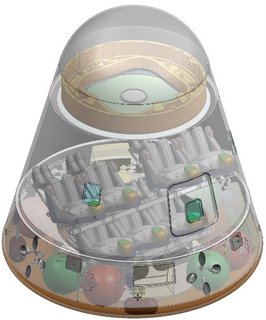

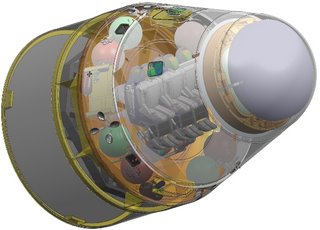

How Dragon would connect with the International Space Station:

How Dragon would connect with the International Space Station: Dragon docking to the Internation Space Station:

Dragon docking to the Internation Space Station: